Feedall specializes in designing and engineering custom bar and shaft feeders. Their specialty is solving complex needs. Feedall’s engineering team has years of extensive experience in mechanical motion, complex and detailed machine design—all to deliver creative and robust solutions.

Feedall has a variety of feeders to choose from. Browse small diameter and short length automatic bar feeders or magazine-style bar feeders. Feedall long bar feeders and thin wall feeders can be used with all types of machining equipment and special machines.

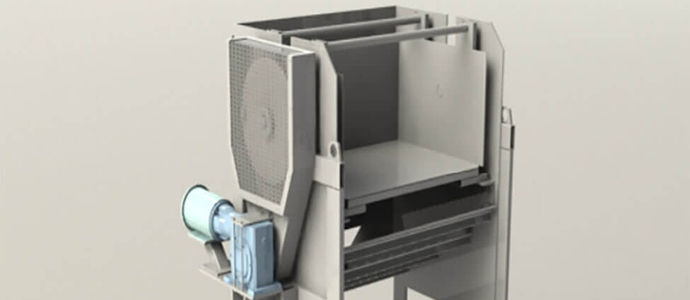

Feedall orientating part feeders are built to run 24/7, 365 days a year. Orientating part feeders for automation systems can be suited to your company and industry’s specific needs. This line includes small parts, heavy duty and hopper part feeders.

These feeders are designed specifically to automatically feed random loaded sliding, rolling headed or hanging parts. Our customers can take comfort in knowing that Feedall’s designs reflect more than 70 years’ worth of successful real-world applications.

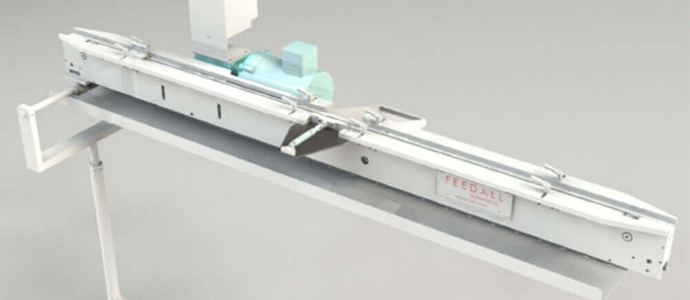

Feedall’s custom automation conveyors are efficient, robust, effective and have been proven to increase manufacturing speeds, productivity and profitability. Their conveyor line includes bidirectional, thru feed, centerless and cooling conveyors.

There are a number of conveyor belting types and models available as well. Feedall conveyors offer entrance, intermediate and exit capabilities for a wide variety of machine processes including centerless grinding, belt finishing, heat treating and assembly.

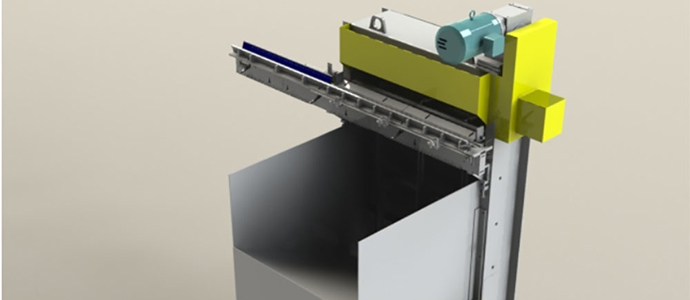

Bulk material handling solutions for custom machine design. Feedall’s complete line of tub and box dumpers, part metering and escapement systems, bulk part elevators and automation part accumulation tables gives our customers a variety of solutions.

We’re able to meet the needs of our clients by continuously keeping production moving. Feedall’s custom-built bulk part elevators provide exemplary parts handling automation. Discharge heights can be custom-made to suit specific needs.